How Does Casting Work

Discover the fascinating world of aluminum casting with our engaging and easy-to-follow video! Whether you're a curious beginner or simply love learning how things are made, this video offers an informal and approachable introduction to the process. You'll gain insights into the art and science behind turning raw aluminum into practical and artistic creations. Perfect for anyone who appreciates creativity and craftsmanship, it’s both informative and fun to watch. Don’t miss the chance to see something incredible come to life—press play now!

Creating The Pattern

Tell Us What You Want

We Start Designing

You Agree On Design

We Print The Pattern

Making a Pattern Board

Install on a pattern Board

Draw Flood Lines

Make Sure It Fits The Flask

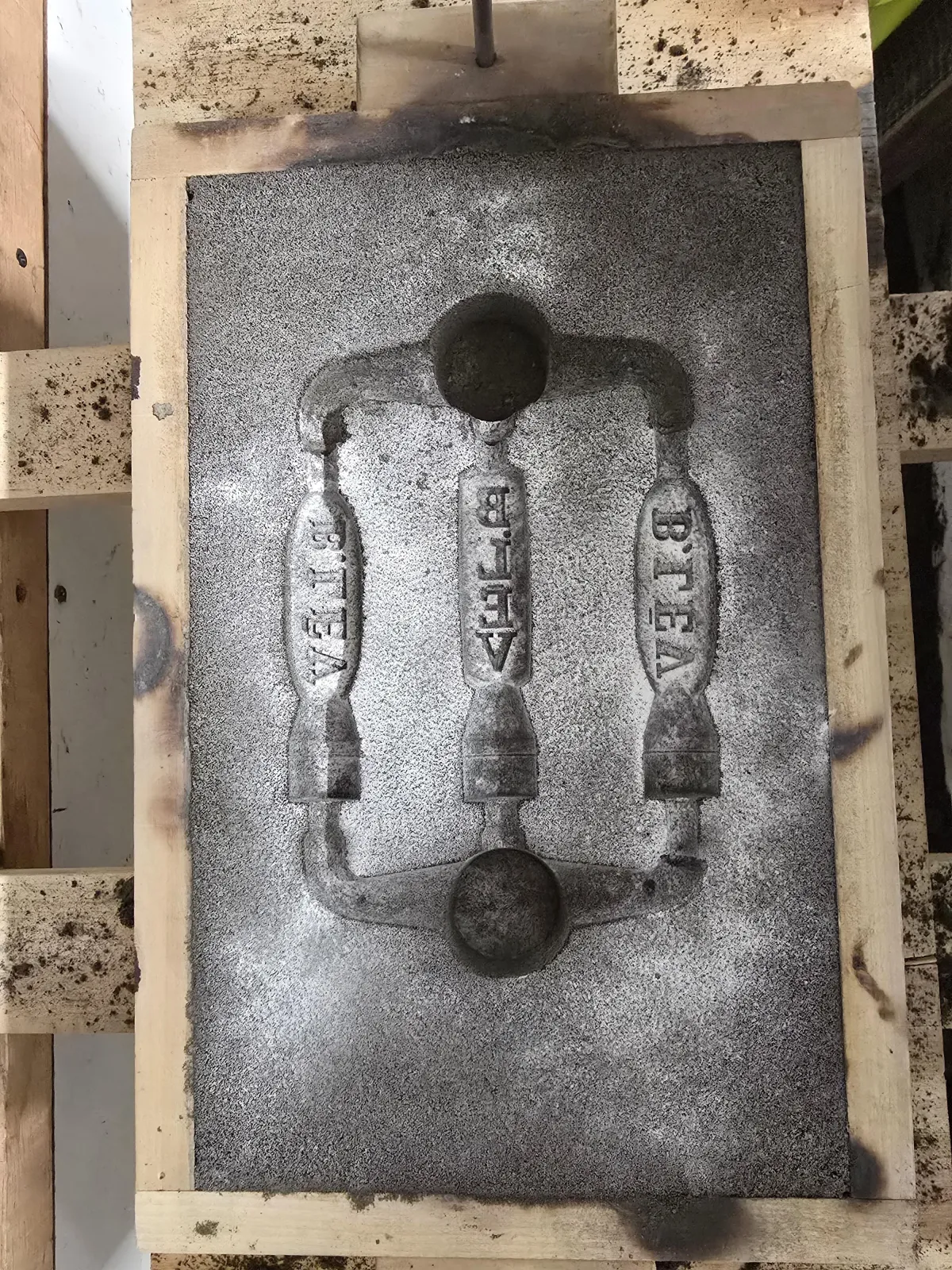

Sand Packing

Put Pattern In Flask

Add Parting Compound

Start Adding Filtered

Repeat on the other Side

Heating The Aluminum

Turn The Kiln On

Put Ingots in the kilm

Add Flux & _

Preparing the flask for the Pour

Make a small divot

Dig drain holes with the tool

Remove & clear the inside of the mold

Preparing the Pour

Add Flux and ___ once more

Add more aluminum when needed

Check the temp of the aluminum.

Put Gear On to keep yourself safe

Pouring

Taking the aluminum and slowly pouring it into the crater

Making sure it came out of the other side to avoid air pockets

Put the aluminum back

Cooling

Let the aluminum cool for 10 minuets

Start to take the flask apart in a tote to save the dirt

Start taking the dirt off the mold

Finalizing & Finishing

Let the metal cool for another 30 mins

Cut the spills off the mold

File off whats remaining

FAQS

What is the maximum oder quantity for a business design?

The maximum amount of items your business can take would be 500.

(The more you order for your business the longer it will take to come.)

I'm a retail store owner how many items can i get at once for my stock?

50-100 items depending on the size.

Do you mentour

As of now we are working on setting up monthly classes to teach everyone how to make this work.