Custom Aluminum Casting

Coral City Foundry

From a serving to casting

After years serving as a Gunnery Sergeant in the United States Marine Corps, I traded my rifle for a crucible. My mission now? To handcraft each USMC chevron with the same discipline, pride, and precision I demanded from my Marines.

Custom Aluminum Casting

Coral City Foundry

From a serving to casting

After years serving as a Gunnery Sergeant in the United States Marine Corps, I traded my rifle for a crucible. My mission now? To handcraft each USMC chevron with the same discipline, pride, and precision I demanded from my Marines.

The Story of Coral City Foundry

The Story of Coral City Foundry

The Story of Coral City Foundry

In 1978, I packed my very first sand mold and poured my first casting. I was just an eighth-grader in shop class, but the moment felt ancient rooted in the raw, elemental dance of earth, wind, fire, and water. Each element playing its part in a transformation that felt almost magical.

Green sand crushed olivine, bentonite clay, and water was packed tight around a wooden pattern. Once the pattern was pulled free, it left behind a perfect hollow, waiting to be filled. Aluminum, melted in a clay graphite crucible inside a brick kiln, glowed like liquid sunlight. A humble venturi burner, mixing propane and air, pushed the temperature past 1700 degrees. Then came the moment: molten metal meeting sand, steam hissing, heat shimmering. When the metal cooled, the pattern was reborn in solid form.

The world may have changed since those first ancient pours 5,000 years ago but the process itself hasn’t. At Coral City Foundry, we honor that timeless tradition. Each casting is a small act of resurrection, a unique creation brought to life in fire and sand.

Even now, as I brush away the grains to reveal a new piece, I feel the same thrill I imagine those first artisans must have felt an unshakable joy in turning raw metal into something both useful and beautiful.

Welcome to Coral City Foundry where history is recast with every pour.

Terry Dressel's Account Commercial Campaign

This ongoing commercial campaign produces smart branded shorts promoting the luxury Terry Dressel's Account community. Mixing stunning aerial shots with family lifestyle segments, we created an extended narrative across a series of 1-2 minute spots aired on local cable and the brand's social channels. Smart SEO and social promotion of the videos drove strong interest in Highland Creek from prospective new residents. Our work showcases adept brand messaging through creative, continuity-driven short form video ads.

The Story of Coral City Foundry

The Story of Coral City Foundry

The Story of Coral City Foundry

In 1978, I packed my very first sand mold and poured my first casting. I was just an eighth-grader in shop class, but the moment felt ancient rooted in the raw, elemental dance of earth, wind, fire, and water. Each element playing its part in a transformation that felt almost magical.

Green sand crushed olivine, bentonite clay, and water was packed tight around a wooden pattern. Once the pattern was pulled free, it left behind a perfect hollow, waiting to be filled. Aluminum, melted in a clay graphite crucible inside a brick kiln, glowed like liquid sunlight. A humble venturi burner, mixing propane and air, pushed the temperature past 1700 degrees. Then came the moment: molten metal meeting sand, steam hissing, heat shimmering. When the metal cooled, the pattern was reborn in solid form.

The world may have changed since those first ancient pours 5,000 years ago but the process itself hasn’t. At Coral City Foundry, we honor that timeless tradition. Each casting is a small act of resurrection, a unique creation brought to life in fire and sand.

Even now, as I brush away the grains to reveal a new piece, I feel the same thrill I imagine those first artisans must have felt an unshakable joy in turning raw metal into something both useful and beautiful.

Welcome to Coral City Foundry where history is recast with every pour.

Coral City Foundry

The Process

Step 1 Pattern

Design and prepare the chevron pattern with precise dimensions and clean draft angles.

Step 2 Mold

Pack green sand (crushed sand, clay, water) around the pattern; remove to reveal the mold cavity

Step 3 Melt

Charge the crucible and heat the aluminum to pour temperature; skim impurities.

Step 4 Pour

Fill the mold. Let heat and time do their work. Break the mold, reveal the raw casting.

Step 5 Finish

Cut gates, fettle, sand, and polish. Inspect. Only the best earns the right to be worn.

Terry Dressel's Account Commercial Campaign

This ongoing commercial campaign produces smart branded shorts promoting the luxury Terry Dressel's Account community. Mixing stunning aerial shots with family lifestyle segments, we created an extended narrative across a series of 1-2 minute spots aired on local cable and the brand's social channels. Smart SEO and social promotion of the videos drove strong interest in Highland Creek from prospective new residents. Our work showcases adept brand messaging through creative, continuity-driven short form video ads.

Coral City Foundry

The Process

Step 1 Pattern

Design and prepare the chevron pattern with precise dimensions and clean draft angles.

Step 2 Mold

Pack green sand (crushed sand, clay, water) around the pattern; remove to reveal the mold cavity

Step 3 Melt

Charge the crucible and heat the aluminum to pour temperature; skim impurities.

Step 4 Pour

Fill the mold. Let heat and time do their work. Break the mold, reveal the raw casting.

Step 5 Finish

Cut gates, fettle, sand, and polish. Inspect. Only the best earns the right to be worn.

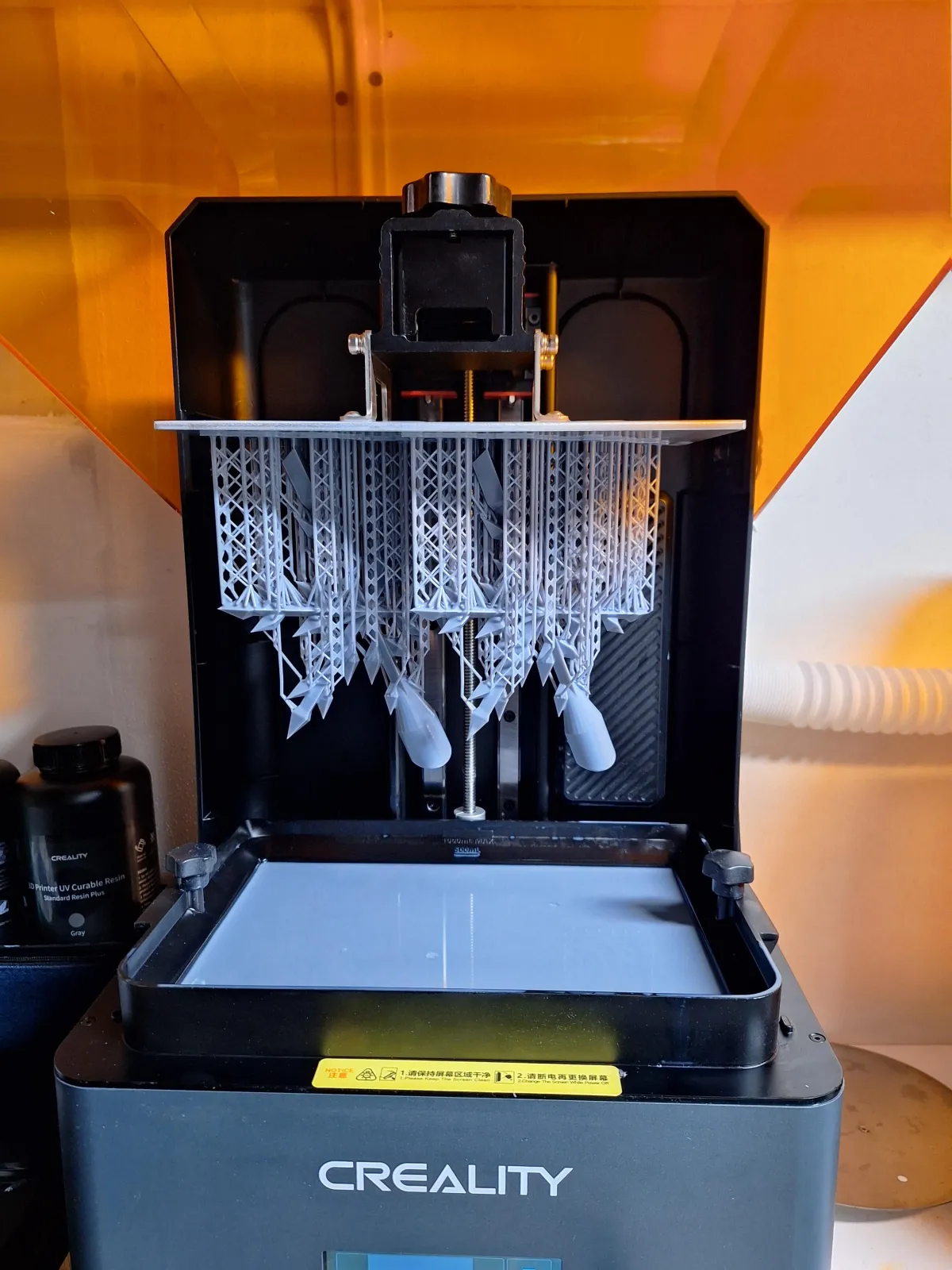

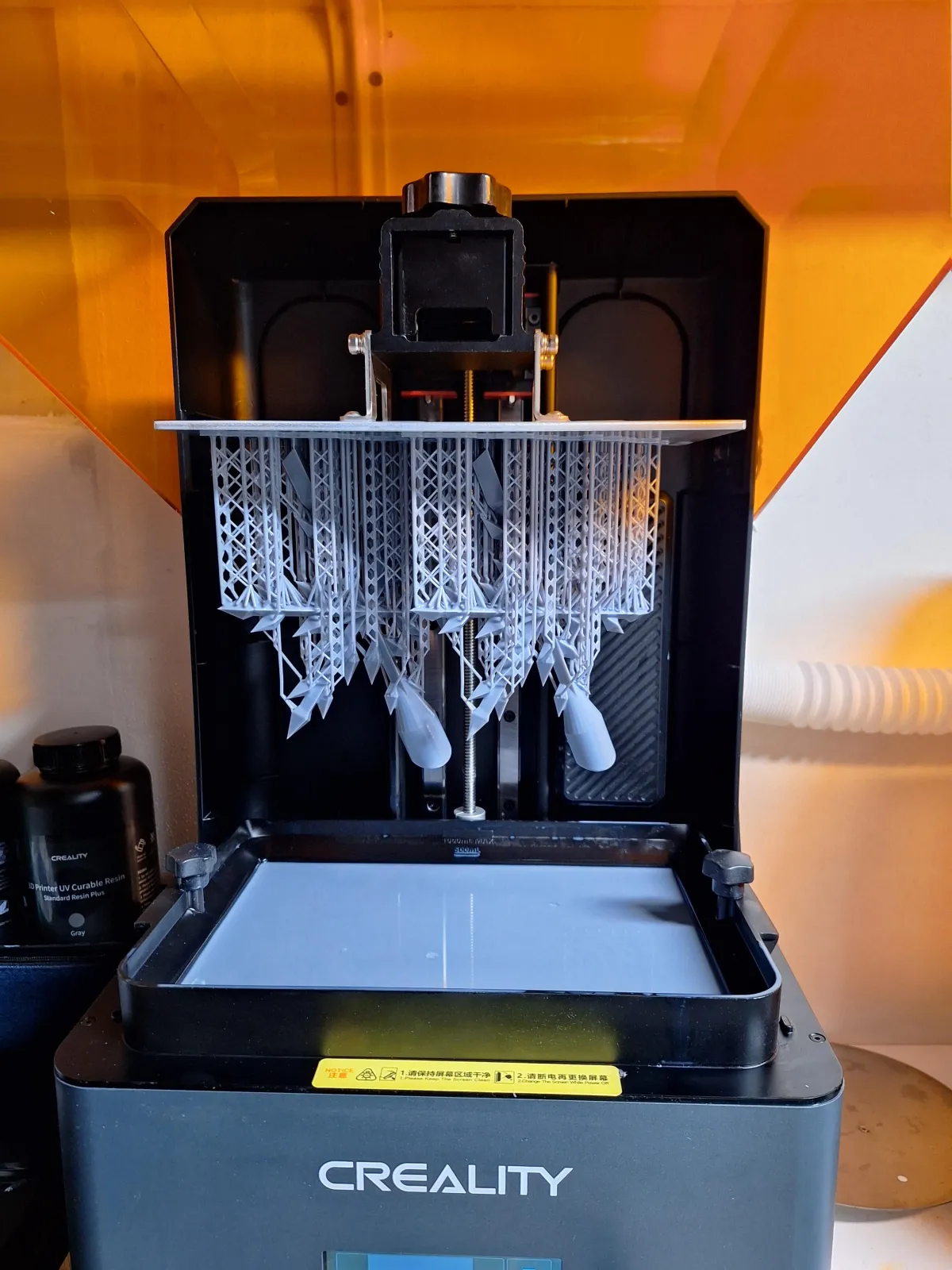

Explore Our Creations

He we have uploaded every single creation we have ever made.

“No creation is ever the same” — Terry D

Small list of creations we have made

Chevrons

Wine Stoppers

Train Reversers

Pumpkins

Snowflakes

FAQS

How do I order something?

You need to reach out to Coral City Foundry via email: [email protected] to put a request in.

How do I order something custom?

When you order something custom it can go two ways.

1. You can submit your own rendition that is 3d printable and we will 3d print it for you and then we will begin casting.

2. We design your rendition into a 3d CAD drawing. Once approved we 3d print it. Then from there we cast it.

How long before i can get my product?

Stock items are cast in limited quantities and available until sold out.

Custom orders are scheduled based on availability. Depending on the complexity it will take from 2-6 weeks

Do you whole sale?

Yes. Provided a predetermined quantity that can be made over a set time in batches.

Example: 15 castings 4 times over 4 months. 60 total castings.